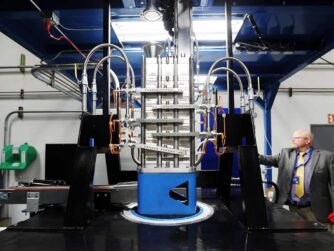

This week Jeff Bassler, founder of Prodigm joins me on the podcast. Prodigm is a premier maker of production-focused filament winding controls and software solutions.

On this episode, Jeff will share some background of their company and a recent case study of helping Duoline Technologies improve their process. Duoline produces RICEWRAP®, a protective wrap of fiberglass epoxy externally applied and bonded to steel pipe for external corrosion protection on downhole tubing.

The team at Duoline had challenges with the current filament winding equipment used to produce this product line. Using Prodigm’s open platform CNC controls and software installed on their filament winding fiberglass tubular product line greatly improved the quality of their parts.

Jeff started Prodigm back in 2008. Having over 13 years of experience in controls and software engineering already, Jeff was completely intrigued by the possibilities offered by filament winding different laminate structures and started developing the first algorithms.

Now, 13 years later, having customers across the continental US, Prodigm’s primary focus has not changed. Getting a machine running is one thing; tailoring it to run for their customer’s specific wants is the most rewarding part.

They’ve contributed to the manufacturing of light poles, composite rifle barrels, ductwork, rocket fuselages, rocket fuel tanks, oil well-lining systems, and lightweight robotic arms—just to name a few! You can learn more about their company by visiting www.prodigm.net.

Podcast: Play in new window | Download