This week we welcome Brian Evans of Globe Composite Solutions on the show. Originally founded in 1890 as a sheet rubber products company in downtown Boston, Globe has evolved into a full-service, leading-edge developer of specialty non-metallic materials for military, medical, material handling, industrial, oil field and marine applications.

This week we welcome Brian Evans of Globe Composite Solutions on the show. Originally founded in 1890 as a sheet rubber products company in downtown Boston, Globe has evolved into a full-service, leading-edge developer of specialty non-metallic materials for military, medical, material handling, industrial, oil field and marine applications.

We’ll be discussing Globe’s history, their unique services and the primary markets they serve.

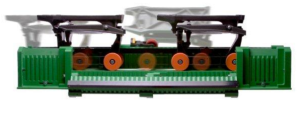

Brian will be sharing some case studies including a large parcel company faced with the question of what to do with its almost 20-years-old, aging tilt-tray system. Completely replacing each system would have cost between $5-$7 million and take over 6 months to accomplish. Unfortunately, this company could not afford to take each system down for such an extended period of time, nor shoulder such a large financial burden.

Globe was able to take the existing aluminum carriage and create a part made of composites. Globe engineers designed the lightweight carriage to fit in the existing system’s metal track and to be interchangeable completely with the existing aluminum carriages. The new composite carriages are 30% lighter in comparison with the former aluminum ones and their highly concentric wheels greatly reduce rolling friction.

Globe was able to take the existing aluminum carriage and create a part made of composites. Globe engineers designed the lightweight carriage to fit in the existing system’s metal track and to be interchangeable completely with the existing aluminum carriages. The new composite carriages are 30% lighter in comparison with the former aluminum ones and their highly concentric wheels greatly reduce rolling friction.

You can find other case studies like this by visiting www.globecomposite.com.

Podcast: Play in new window | Download