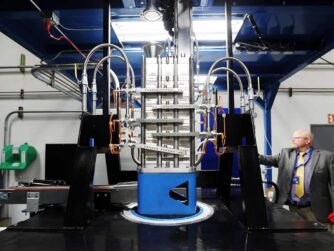

We’ve all heard the saying “an ounce of prevention is worth a pound of cure” at some point in our lives. It’s a statement that’s very often neglected by chopper and gel-coat gun operators when it comes to their equipment. You can see what I mean when you look at this photo to the right. This is a photo I took from an equipment audit I did for a customer.

We’ve all heard the saying “an ounce of prevention is worth a pound of cure” at some point in our lives. It’s a statement that’s very often neglected by chopper and gel-coat gun operators when it comes to their equipment. You can see what I mean when you look at this photo to the right. This is a photo I took from an equipment audit I did for a customer.

Whether it’s chopper systems, gel-coat systems, RTM or even simple wet-out dispensers, all equipment has to be properly maintained in order to work effectively. Just the other day I had a customer who was shocked to receive a repair bill of over $1,000 for two gelcoat guns.

The bulk of this bill were parts on the gun that had to be replaced due to poor maintenance. The previous gelcoat operators had not bothered to keep them clean and let hardened gelcoat set up inside them, rather than take them apart and let the parts soak in acetone.

It’s important so important to train chopper and gelcoat operators so that they know the proper maintenance procedures when guns and pumps.

On today’s show, I’ll be discussing some of the checklists every operator should be going through before, during and after they’ve finished spraying.

Here are some quick tips that I recommend for everyone gun operator and maintenance superviser:

- Make sure the gun head is properly flushed out with acetone when done spraying. If it’s an internal mix gun, make sure the operator is pushing the flush button every time he stops spraying.

- Take the catalyst tip and material tip off at the end of the day and let soak in acetone overnight.

- Make sure the gun is always hung up with the gun head facing down, so catalyzed material does not seep back into the gun head.

- Wipe any overspray or other debris off of the pump shafts (for both catalyst and resin pumps). If possible create a protective barrier or shield to keep the pump shaft clean.

- Make sure the throat of the pump always has throat seal oil.

- Dump the resin or gelcoat pressure at the end of the day.

A huge part of unnecessary equipment expense comes from lack of proper maintenance. This costs can be greatly reduced by simple preventative maintenance.

Podcast: Play in new window | Download